Choosing the Right Rims: Things You Need to Know

Posted on Jun 19, 2016 in Technology | 2 comments

Custom wheels are probably the quickest way to enhance the appearance of your vehicle and give it a unique, personalized style. Aftermarket wheels come in a huge selection of designs and sizes and depending on your goal, they can not only be used to improve the vehicle’s look, but they can also considerably boost overall performance.

So what rims would be best for your ride? Well, when it comes to wheel styles, with an assortment of offerings available on the market today, your choice is literally limited to your fantasy. But, before talking about the appearance and performance capabilities, there are several important basics you need to know to choose the right wheels for your car, truck, or SUV.

What wheels are right for your ride?

Construction

There are several types of wheel construction. Each method varies in strength, weight, durability, and price.

Cast aluminum wheels

These are the most common – and the lowest priced – wheels that are typically found on factory vehicles. Cast aluminum wheels are manufactured by putting molten aluminum into a wheel-shaped mold. This can be accomplished two ways: gravity casting, which is the most basic process, and low pressure casting, which allows creating of more dense wheels.

Pros: cheap to produce, strong enough for the majority of consumers

Cons: heavy, not as smooth as forged wheels, nearly impossible to repair.

Flow-Formed / Rolling-Forged wheels

Flow forming process starts out with a low pressure type of casting, but then it uses special high-heat and high-pressure spinning machine to form the outer hoops. The resulting wheel is similar to a forged wheel but it’s not as expensive in production.

Pros: lighter and stronger than cast wheels, retain low price, better looks and wider selection of styles.

Cons: still has limits if a cast wheel, limited custom fitments.

Flow-forming process

1-piece “Monoblock” forged wheels

Monoblock wheels are created by forcing a round bar stock of aerospace-quality aluminum alloy between the forging dies under extreme pressure. Forging is an ultimate technology in one-piece wheels. It creates a finished wheel that is very dense and lightweight. Naturally, the costs of assembly make this type of wheel sit on the higher end of the market price range.

Pros: lightest of the forged wheel types.

Cons: high price, hard to repair when seriously damaged.

Asanti Monoblock Wheel

2-piece forged wheels

2-pieced forged wheels divide into another two classes. Some manufacturers bolt the center of the two-piece wheel into a cast or spun rim section, while others weld the center to the hoop on the backside of the wheel. The prices for 2-piece wheels start well below the average 3-piece wheel, but two-piece rim are not available in as wide range of applications. Higher-end 2-piece wheels may use forged rims and forged centers, which make them significantly pricier.

Pros: cheapest in forged wheels; very light, very strong and can be repaired.

Cons:limited widths options available, lip on welded 2-piece wheels cannot be easile chrome plated or painted, since it has to be welded on; bolted construction 2-piece wheels are more rarely found in the market.

MHT 2-piece Luxury Wheel

3-piece bolted construction forged wheels

Due to the high cost of tooling, and CAD technologies involved, three-piece forged wheels are commonly the most expensive type of wheel construction. The wheel consists of three main pieces (obviously) – the center, the outer lip and the inner hoop. All parts are normally held together with bolts and sealant applied in or on the assembly to seal the wheel. Sometimes three-piece wheels can be seen with cast aluminum centers. Such wheels are naturally cheaper, but the quality and weight of the cast centers are not as good as forged.

Pros: come in widest range of widths; almost unlimited fitments; easiest of all wheel constructions to repair; the richest selection of styles available.

Cons: most expensive of all wheels; require truly skillful installation as seal can be damaged easily in the inexperienced hands.

Choosing the right size

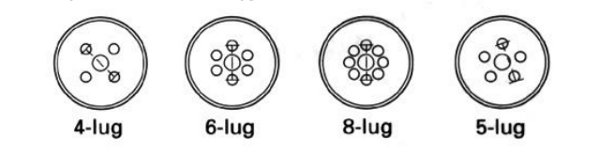

When changing wheels, be sure to select a replacement with a bolt pattern or circle that matches the OEM pattern of your vehicle. For example, the 2010 Camaro has a 5X120.7 wheel hub, which indicates that the wheel has five bolt holes on a circle with a diameter 120.7mm. More and more manufacturers are making their wheels with two bolt patterns to expandthe number of fitments the wheel applies to. For example: a wheel with a 4-100/114.3 bolt pattern has 8 lug nuts and will fit both 4-100mm and 4-114.3mm wheel hubs.

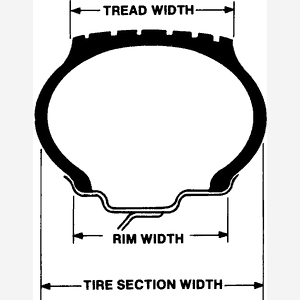

Another parameter to look at is the wheel size, which is the diameter of the wheel in inches where the beads of the tire sits on the wheel. The diameter designations for both the tire and the rim must be of the same value. Thus, a 17’’ tire must be mounted only on a 17’’ rim. Also, check what rim widths are recommended by the manufacturer of tires that you consider. To reach the best balance between ride, handling and treadwear, select a rim width in the middle of the manufacturer’s recommended range. To improve cornering traction and steering response, opt in for the max rim width in the range. For example, if the tire size is P225/70R15 and the recommended rim width range is 6’’-8’’, select the 7’’ rim for optimum performance and 8’’ for better cornering. If you’re choosing wheel for off-roading, select a rim near the minimum recommended width value.

The flange-to-flange wheel width should never be more than the tread width of the tire.

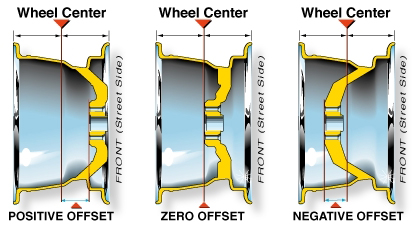

In addition to choosing wheels with the correct bolt pattern and rim width, you should also choose a wheel with the correct offset, unless you’re building a hellaflush of course. The offset is the distance from the hub-mounting surface to the rim’s true centerline. It’s measured in milimeters and can be negative, zero, or positive.

The offset of the rim is what locates the tire/wheel assembly in relation to the suspension. That’s why in order to maintain handling characteristics and avoid extra loads on bushings and ball joints, it is important to keep the front axle offsets on the FWD and AWD vehicles to the OEM specifications. Using the proper positive or negative offset for the vehicle’s rear wheels is important, but less so than using it at the front where the bearing load situation is critical.

Selecting aftermarket wheels, make sure that their centerbore (the size of the hole on the back side the wheel that centers it over the mounting hub of the car) is equal or greater that that of the hub, otherwise you will not be able to mount it on the car.

wow, good info!

I have two (2) vehicles:

1. 1995 Ford Crown Victoria LX, P215 70R15; 4.6LV8

2. 2000 Dodge Dakota pick-up SLT, 3.9 L, V6

P235 75/15

I want super (ultra strong) wheels, I do not care about looks at all ! I do not want to have flat tires or bent wheels after hitting “Chuck-Holes” in road.

I do not go “Off-Road”

Should I buy “three (3) piece bolted construction forged wheels” and, if so, are these forged steel or forged aluminum ????